ALCEN is a supplier and/or partner of large international fundamental or applied research programs. The group develops and supplies mechanical components and complex multi-technology systems integrated into particle accelerators, high power lasers, experimental nuclear reactors and telescopes.

Power Lasers

by subsidiaries:

-

read more

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Contact

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

-

read more

With over 20 years of experience, ITOPP (formerly ITHPP) has become the French leader in high pulsed-power and high-power microwave technologies.

Driven by customer specifications, ITOPP designs and manufactures adapted and highly innovative systems linking these technologies to scientific research and also to civil and military applications.

High Pulsed-Power technologies allow for the amplification of electrical power delivery over a shorter burst period. Since energy is the product of power over time, by maintaining a constant flow of energy and reducing the duration of the pulse, it is possible to achieve powers in excess of one hundred Gigawatts.

High-Powered Microwaves are very highly charged electromagnetic pulsations capable of disturbing and even destroying electronic components used in today's increasingly complex systems. The interest in these high-powered microwaves are due to the vast array of uses, varying from more classic uses (such as Radar) to more advanced technologies, such as those used in Electronic Warfare.

- Website

- Contact

- Location on map

- +33 5 65 33 43 30

ITOPP on ALCEN's website

Defense & Security Airborne drone

Defense & Security Simulation

Power Lasers

ALSYMEX and ITOPP are involved in the Megajoule Laser (LMJ) program, offering innovative solutions and services meeting stringent requirements.

ITOPP provides the switching functions of Megajoule laser energy benches.

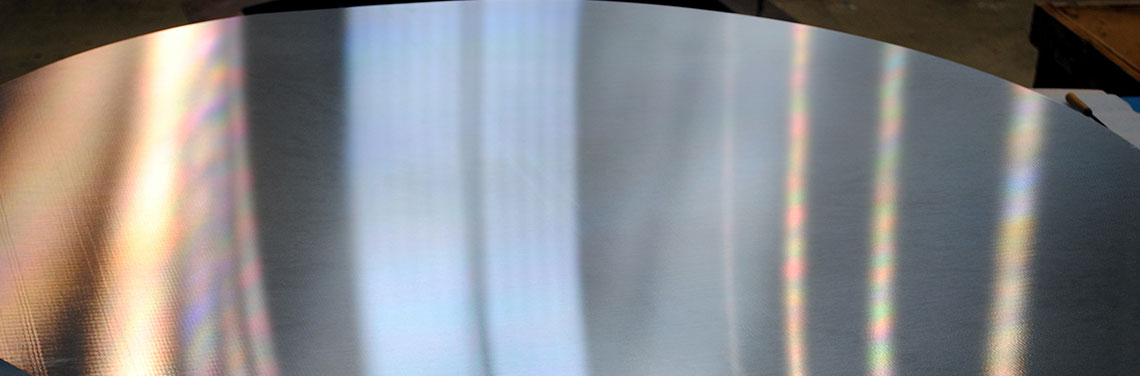

ALSYMEX, via its involvement in many subassemblies of laser chains, is one of the CEA's main partners, handling:

- Design, production, clean room assembly and on-site integration of amplifying sections, laser transport lines and certain subassemblies of the frequency conversion system

- Manufacturing of adaptive mirrors and protective panels of the experimental sphere, etc.

ALSYMEX also maintains in operational condition various equipment parts of the laser chains and of the experimental hall, and carries out anti-reflection treatments for all LMJ optics (SOL GEL).

This unique expertise, developed within the context of this key project of the French nuclear simulation program, is also able to respond to the other demands of large high-power laser projects. ALSYMEX is therefore involved in the European ELI project, in particular in the Romanian pillar, being responsible for:

- Design, manufacture and on-site installation of a interaction chamber between high energy electrons and photons to generate gamma rays

- Design, manufacture and on-site installation of key components of 10 PW laser beam transport systems

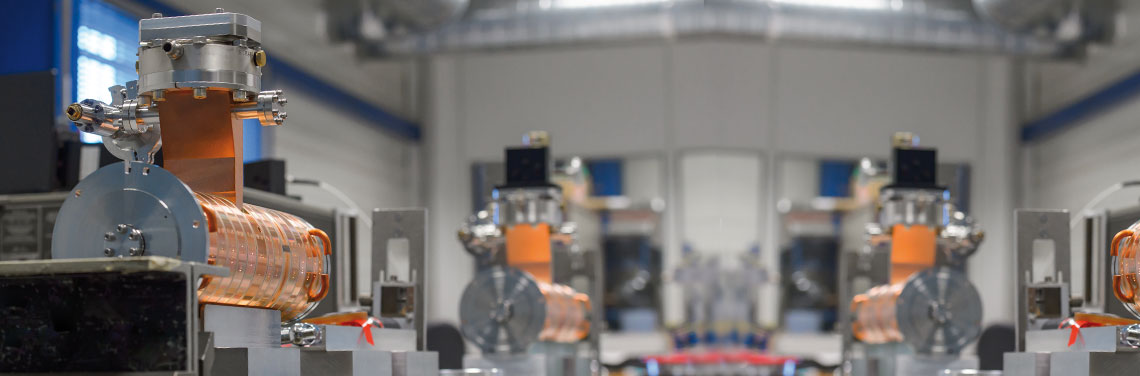

Particle Accelerators

by subsidiaries:

-

read more

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Contact

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

-

read more

For more than 30 years, IRELEC has been involved in the design and manufacture of high technology equipment for demanding applications, such as Large Research Infrastructures (particle accelerators, power lasers, etc.) and Medical Research Centers.

Its excellence is reputed in France as well as worldwide: IRELEC supplies and maintains in operational conditions equipment all over Europe, in the Americas and in Asia.

IRELEC's commitment to its customers is based on its ability to adapt robust solutions to their specific constraints, thanks to IRELEC expertise in high precision mechanical engineering, robotics, ultra-high vacuum technologies and cryogenics.

IRELEC's Main Product Lines:

- Opto-mechanical systems for X-ray beam transport and conditioning

- Robotic systems for complex processes, such as biological sample manipulation in cryogenic environments

- Test benches (characterization of power electronics, detection of pollution by nanoparticles, control of magnetic structures, etc.)

- Website

- Contact

- Location on map

- +33 4 76 44 12 96

IRELEC on ALCEN's website

Medical & Healthcare Biobank

-

read more

PMB specializes in the assembly of dissimilar materials by vacuum brazing. It makes complex mechanical components for global medical equipment companies. These "metal/metal" or "ceramic/metal" assemblies are integrated into X-ray tubes for scanners, radiotherapy machines or medical implants in the form of hermetic feedthroughs.

It also develops products used in Scientific Research, Defense, Space and Nuclear.

It has a production site in France and a second site in Northern Africa through its subsidiary PMB Tunisia, offering its clients a reliable supply at an optimized cost.

- Website

- Contact

- Location on map

- +33 4 42 53 13 13

PMB on ALCEN's website

Aeronautics & Space Mechanical components

Aeronautics & Space Vision & Inspection

Medical & Healthcare Medical machines

Medical & Healthcare Mechanical & electronic components

Particle Accelerators

Whether for fundamental research (nuclear and particle physics) or applied research (synchrotrons and neutron sources) or industrial applications (medical and non-destructive testing), ALSYMEX, IRELEC and PMB are involved in design and manufacture for major particle accelerator programs.

ALSYMEX

ALSYMEX designs and manufactures mechanical components and subassemblies that comply with restrictive specifications in terms of dimensions, precision, pressure and cleanliness.

For example, ALSYMEX is involved in the X-FEL X-ray free-electron laser program, constructed in Hamburg within the context of a European collaboration. The company was responsible (in collaboration with the CEA) for the assembly of the one hundred cryomodules of the accelerator.

The assembly operations were organized around eight special workshops, some in an ISO 4 ultra-clean environment, combining assembly, welding, inspection, vacuum, laser tracker metrology and handling expertise.

IRELEC

For over 25 years, IRELEC has designed and manufactured highly reliable optomechanical components for soft and hard X-ray beamlines of synchrotron light sources around the world (France, Germany, England, Spain, Sweden, USA, China, Australia, etc.): high-stability modular mirror systems, Kirkpatrick-Baez systems, LAUE monochromators, dynamic mirror benders, beam attenuators, micro-ovens for tomography experiments and X-ray diffusion.

IRELEC also designs and manufactures robotized systems for transferring and handling frozen biological samples (macromolecules).

PMB

PMB designs and manufactures a wide range of components and subsystems at the heart of electron or hadron accelerators, whether these are hot or supraconducting:

- Beam Position Monitors (BPM) used to measure and check the exact position of the electron beams. In addition, PMB manufactures SMA type penetrations

- Electron guns generating the particles that are then accelerated

- Kicker ceramic vacuum chambers

- Power couplers for injecting the RF power necessary for operation of the supraconducting cavities while guaranteeing the thermal and atmospheric transitions between these and the outside environment

- RF windows ensuring separation between the ultra vacuum at the core of the accelerator and the outside environment while guaranteeing propagation of the RF power necessary for operation of the cavities

- Copper accelerating sections for linear accelerators (frequencies between 3 and 9 GHz)

PMB designs, manufactures and assembles all of the components of the beam lines in particle accelerators. The company also activates the gun and performs the high-frequency conditioning.

Astrophysics

by subsidiaries:

-

read more

ADR designs and manufactures high-precision ball bearings in a wide range of sizes (from 1 mm in bore size to 330 mm in outside diameter).

These highly sensitive bearings are found in viewfinders, gyro-stabilized systems, optoelectronic and avionics equipment, infrared pointers, encoders, motors, etc.

As a subsystems developer, ADR develops and offers integrated technical solutions, incorporating a variety of different functions to the bearings.

ADR also designs and produces actuators specifically adapted to highly complex systems.

- Website

- Contact

- Location on map

- +33 1 64 70 59 50

ADR on ALCEN's website

Defense & Security Mechanical & electronic components

Energy Oil & Gas

Aeronautics & Space Mechanical components

-

read more

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Contact

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

-

read more

A subsidiary of the ALCEN Group, EPSYL (formerly EPSILON) specializes in high-tech civil and military system architectures, more particularly in terms of thermal engineering.

It is one of the few private companies supported and classed as a Contractual Research Structure by the French Ministry for Research and Industry. It works with key European players in Space, Aeronautics and embedded systems:

- Analysis of phenomena in thermal engineering, electrothermal engineering, thermal fluid engineering, thermal mechanical engineering in the fields of architecture, modeling, simulation and testing for both systems and equipment or components

- Expertise in the field of system integration and system simulation, predictive reliability, characterization of materials, processes or thermal products

- Development of thermal and multi-physical simulation tools and platforms

- Website

- Contact

- Location on map

- +33 5 61 00 19 19

Astrophysics

ALSYMEX, ADR and EPSYL work in the field of astrophysics.

ALSYMEX

ALSYMEX offers the scientific community in the field of astrophysics mechanical and optomechanical assemblies integrated into ground or on-board telescopes.

ALSYMEX has therefore been heavily involved in the construction of a prototype of a small size telescope (SST) for the future CTA European program for exploring the universe in gamma rays: production of metallic reflectors and support structures.

ADR

Electro-optical subsystems. ADR supplies integrated bearings for the EUCLID space telescope.

EPSYL

Thermal and multi-physics engineering. EPSYL is in particular involved in the JSWT and M1 Solar Orbiter projects of France's CNES and the ESA.

Experimental Nuclear Reactors

by subsidiaries:

-

read more

Bringing together the expertise and means of four ALCEN subsidiaries, ALSYMEX offers its clients solutions and services with high added value:

- Feasibility studies

- Engineering: machining, welding, vacuum

- Detailed design: mechanical engineering, thermo-mechanics, seismicity, vacuum, optics

- Production of high-precision mechanical and optomechanical assemblies: boilerwork, joint welding, machining

- Integration of complex systems in ISO 5 to ISO 8 cleanrooms

- Non-destructive testing

- On-site installation

- Maintenance of mechanical, optomechanical, vacuum and high voltage systems for large scientific instruments and nuclear-capable sites

- Large program management

ALSYMEX operates in the fields of Defense, Energy, Aeronautics and Large Research Infrastructures.

- Website

- Contact

- Location on map

- +33 5 56 13 84 44

ALSYMEX on ALCEN's website

Defense & Security Engineering, Maintenance & Services

Defense & Security Mechanical & electronic components

Energy Nuclear

Energy Engineering, Maintenance & Services

Energy Oil & Gas

Aeronautics & Space Engineering & Maintenance

Aeronautics & Space Mechanical components

Experimental Nuclear Reactors

ALSYMEX plays an active role in the Jules Horowitz experimental fission reactor development program in that it has industrialized the manufacture of the Jules Horowitz Reactor reflectors and has established a dedicated production space for the mechanical assembly of the reflectors.

ALSYMEX is involved in the leading thermo-nuclear fusion programs, and specifically the ITER project. They offer innovative solutions and services suited to the harsh environment of this test reactor:

- ALSYMEX:

- Preproduction cryogenic pumps

- Equipment for poloidal field coil assembly and handling

- Review study for ion source design

- Design and manufacture of mechanical components for diagnostics

- Beryllium first wall panels

- Tungsten divertor subassemblies

- Plasma facing components for RF heating antennas

Further information on ALCEN's expertise and references in the field of nuclear fusion is available at www.alcenforfusion.com